What percent of pump failures are due to a seal or bearing failure? 90%. Find out how you can increase your pump life and miminize process downtime.

Pump Oil Contamination

Wind-blown sand, dust, steam, and rain as well as condensation from thermal cycling-contamination can come from anywhere in an industrial environment. And it does not take much to do a lot of damage. It is nearly impossible to address every potential source of contamination in an industrial setting, but with the added protection of a filter or strainer, risks are minimized.

Wind-blown sand, dust, steam, and rain as well as condensation from thermal cycling-contamination can come from anywhere in an industrial environment. And it does not take much to do a lot of damage. It is nearly impossible to address every potential source of contamination in an industrial setting, but with the added protection of a filter or strainer, risks are minimized.

Pump Oil Viscosity

One of the biggest misconceptions about pumps in the industrial market is that as operating temperature goes up, the viscosity of the oil should go up with it.

In reality, the oil used to lubricate bearings always needs to have a viscosity that makes sense for the load and environment. Taking samples of the oil at regular intervals can be a useful way to check oil performance to diagnose and correct problems early. Too many people wait until a bearing fails completely before they try to fix problems and are unable to determine if a lack of lubrication or a momentary event caused the failure.

Pump Cooling – Water vs. Air

Modern industry demands modern methods of cooling. Without them, bearing temperature can fluctuate widely, increasing chances of oil contamination and promoting the onset of spalling — breaking into fragments. Water cooling used to be the preferred method, however modern bearing housings have enhanced air cooling with axial fans and an effective cooling fin design. Updated air cooling can achieve oil and metal temperature reductions of up to 30°F over previous designs. Even better, these fans come standard with a guarded extension for easy retrofitting. So, if the process needs change, a new fan can be fitted without the need for expensive pump disassembly.

Modern industry demands modern methods of cooling. Without them, bearing temperature can fluctuate widely, increasing chances of oil contamination and promoting the onset of spalling — breaking into fragments. Water cooling used to be the preferred method, however modern bearing housings have enhanced air cooling with axial fans and an effective cooling fin design. Updated air cooling can achieve oil and metal temperature reductions of up to 30°F over previous designs. Even better, these fans come standard with a guarded extension for easy retrofitting. So, if the process needs change, a new fan can be fitted without the need for expensive pump disassembly.

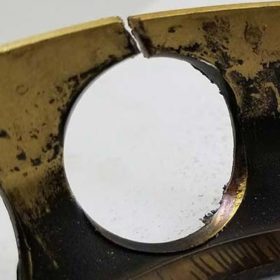

Monitoring Pump Bearing Failure

Users need to look at the entire system — the oil, installation, process, load, and environment. This analysis will identify ways to increase the life of bearings and pumps and prevent expensive machine failures down the line. Pump Monitors can help automate this for you.

Images: ITT Goulds Pumps

Contact Us for Personalized Assistance with Sizing and Selection

ITT Goulds Pumps Four Critical Factors for Longer Pump Life was written by Ryan Utara, a North American solutions engineering manager,

ITT Goulds Pumps Four Critical Factors for Longer Pump Life was written by Ryan Utara, a North American solutions engineering manager,